👩🏫Workshop on Natural Pigment Extraction from Food Waste

Step 1: Fabric Preparation

The fabrics must be made of natural fibers, as synthetic materials do not react well to plant-based dyes.

The fibers in your fabrics can be of two types:

Animal (protein) fibers: wool, hair, and silk.

Plant (cellulose) fibers: cotton, linen, hemp, ramie, and rayon (viscose).

Pre-wash Instructions:

Ask the students to select the types of fabric they would like to work with, preferably second-hand fabrics. Remember to promote the circular economy.

Have them, with the help of an adult, place the fabrics in a solution of water, 3 teaspoons of washing soda, and natural soap. They can either wash the fabrics in a washing machine or let them soak overnight in the washing soda and natural soap solution. Then, let the fabrics dry in the sun and store them until the day of the workshop.

Step 2: Preparing the Fabric for Color Fixation or Mordanting

What is Mordanting?

Mordanting is the process that allows dyes to firmly adhere to textile fibers through the use of mordants—substances that help fix the color onto the fabric. Typical mordants are metallic salts that facilitate this bond. There are various types of mordants, each with specific characteristics and applications:

Metallic Mordants:These aid in binding the dye to the fiber and are particularly effective with natural fibers. Examples include:

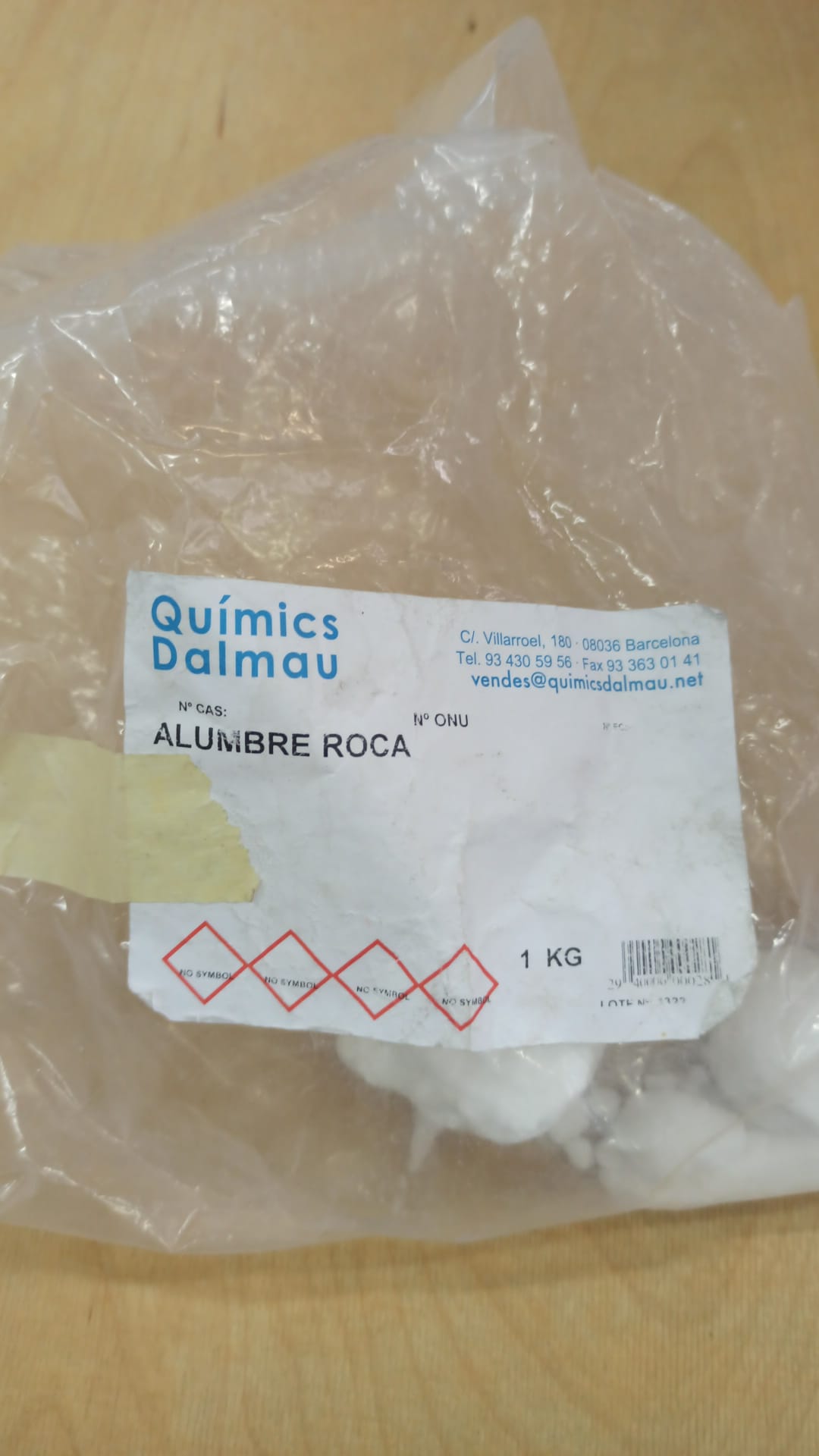

Alum (Potassium Aluminum Sulfate): A widely used mordant, available at herbalists and pharmacies, which is safe and effective.

Iron (Iron Oxide): Can be prepared by placing rusty screws in a mixture of vinegar and water (50/50). This mordant creates darker tones in natural dyes.

Natural Mordants:These are derived from plant-based compounds and are not technically metallic salts but act as fixatives.

Tannins: Found in tree bark, avocado pits and skins, or grape seeds, tannins are natural polyphenols that help fix color. They can be extracted by preparing an infusion of bark or seeds in hot water. This tannin extract is a natural mordant commonly used for cellulose fibers.

Extraction of Tannins from Avocado Cream of Tartar: Commonly used alongside other mordants to enhance fixation and soften the texture of fibers.

Additional Homemade Fixatives:

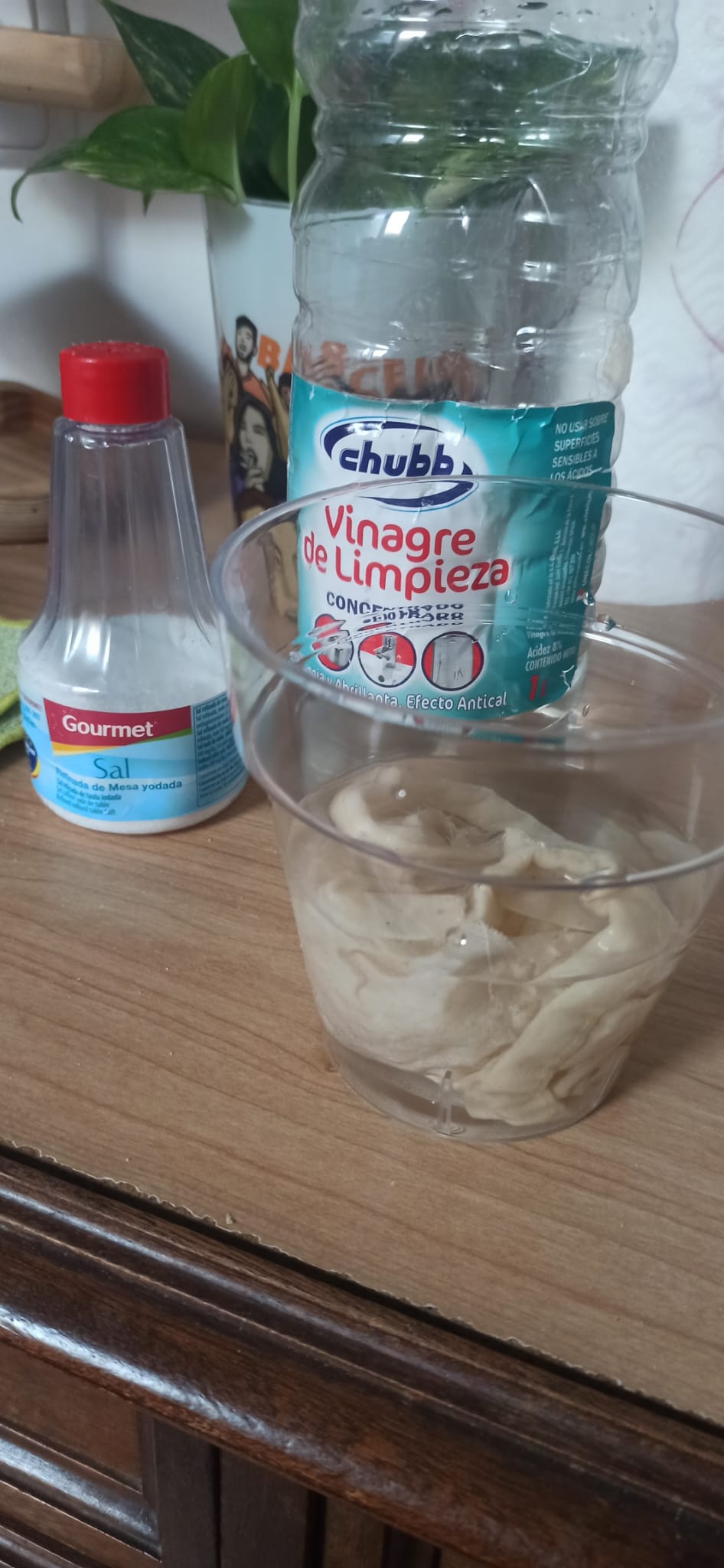

Vinegar with Salt: Helps prepare the fabric for soft dyes and can be combined with other mordants.

Environmental Considerations: Some traditional dye recipes use heavy metals such as chromium, introduced during the Industrial Revolution. However, these are not recommended today due to their toxicity and the challenges of safe disposal. Instead, many natural and safe alternatives can provide equally effective results with a lower environmental impact.

Mordanting Process in the Classroom: To carry out the experimentation, each student group can test a different type of mordanting method, ranging from alum and tannins to vinegar with iron. Following these steps, each group should:

Heat the chosen mordant infusion (without bringing it to a boil) and immerse the fabric to allow maceration for about 40 minutes.

Continuously move the fabric to ensure even fixation.

Let it cool, wring out the fabric, and finally rinse it.

Through this experience, students can observe the variations in color and fixation that each mordant produces, documenting their results and appreciating the impact of sustainable and safe mordanting methods.

Step 3: Preparation of Selected Food Waste

Assign each group of students a different type of food waste to experiment with. Aim to use seasonal waste to promote the concept of food seasonality and explain the importance of eating products according to each season.

Wash and cut the food waste into small pieces to increase the surface area in contact with water.

Place the food waste in pots with enough water to completely cover them.

Simmer the mixture on low heat for at least an hour to extract the pigments. Add more water if needed.

Once the water is dyed, allow the mixture to cool, then strain it to remove the solids.

Step 4: Fabric Dyeing

Each team should immerse their fabric pieces in the prepared dye, ensuring they are completely covered.

Simmer the fabrics in the dye for approximately one hour on low heat to allow the pigments to bind to the fibers.

Remove the fabrics and rinse them with cold water to eliminate excess dye. Let them air dry.

Step 5: Color Recording

As the fabrics dry, invite the students to observe the different tones and shades obtained from the food waste.

Ask them to record the colors in their journals, noting the name of the waste material, the extraction technique used, and a description of the resulting color.

Step 6: Conversion to Powdered Dyes

To convert liquid dyes into powder, use a mortar and pestle to grind the dry residues after extracting the pigments.

If you want to create watercolors, add a natural binder like gum arabic to the powdered dye and mix well. Then, let the mixture dry in transparent containers.

Step 7: Conclusions and Presentation

Conclude the workshop by discussing the results achieved and how students can apply what they learned in future projects.

Encourage students to take home their dyed fabrics and color records to share with their families.

Motivate students to further experiment with creating dyes and to explore other natural pigment sources in their surroundings.

Last updated